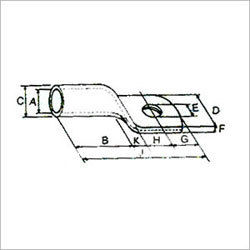

Tubular Compression Cable Lugs

Tubular Compression Cable Lugs Specification

- Thickness

- 0.8 2.5 mm depending on lug size

- Surface Treatment

- Tin plated for corrosion resistance

- Sealed

- Unsealed

- Cable Diameter

- Suitable for 1.5 mm to 630 mm conductor

- Product Type

- Compression cable lug

- Material

- Electrolytic copper

- Application

- Power distribution, switchgears, control panels, electrical installations

- Contact Resistance

- 0.2 m

- Insulation Resistance

- 1000 M

- Diameter

- Corresponds to stud hole size per specification (e.g. 6 mm, 8 mm, 10 mm)

- Terminal Socket

- Closed barrel, tubular entry

- Style

- Tube type, standard barrel

- Fittings

- Crimp (compression fitting)

- Rated Voltage

- Up to 1100 V

- Weight

- Varies as per size (approx. 5g 250g)

Tubular Compression Cable Lugs Trade Information

- Payment Terms

- Cheque

- Delivery Time

- depends on quantity Week

- Sample Available

- Yes

- Packaging Details

- carton packing

- Main Domestic Market

- All India

About Tubular Compression Cable Lugs

With our industry expertise, we are indulged in manufacturing and supplying wide assortment of Tubular Compression Cable Lugs in the global market. Available in varied specifications as per the specific requirements of clients, these cable lugs are manufactured using high quality raw material and cutting-edge technology as per the quality standards. Used for switch cabinets and equipment wiring purposes, these Tubular Compression Cable Lugs are provided at very nominal price to the clients.

Features

- Excellent strength

- Sturdiness

- Corrosion resistance finish

Tinned Type Tubular Compression Cable Lugs

Manufactured from pure electrolytic copper :

* copper lugs & cable terminals from 1. 5 to 1000 mm2 with different stud hole sizes as required.

* lead free electro tin plated to prevent atmospheric corrosion.

* cable lugs are fully annealed to guarantee optimum ductility.

* our all products are as per rohs compliance.

Furthermore, These are available at competitive prices.

Engineered for Secure Connections

Our tubular compression cable lugs ensure robust electrical and mechanical connections, supporting conductor sizes from 1.5 mm to 630 mm and accommodating a range of stud hole diameters. The closed barrel, tube-style design maximizes contact area, resulting in minimal contact resistance for optimal current flow in power distribution systems.

Superior Material and Plating

Manufactured using high-quality electrolytic copper and finished with tin plating, these lugs offer excellent conductivity and corrosion resistance. This ensures durability and long service life even in challenging environments, making them a dependable choice for professionals across electrical, control, and switchgear panels.

FAQs of Tubular Compression Cable Lugs:

Q: How are tubular compression cable lugs installed?

A: Tubular compression cable lugs are installed by inserting the stripped conductor into the barrel and compressing it using a suitable crimping tool. This creates a secure mechanical and electrical bond, ensuring reliable performance.Q: What applications are tubular compression cable lugs suitable for?

A: These lugs are ideal for power distribution, switchgears, control panels, and general electrical installations. They accommodate a wide range of cable diameters, making them versatile for both industrial and commercial settings.Q: When should I use a standard barrel, closed barrel tubular lug?

A: Standard barrel, closed barrel tubular lugs are recommended when you need enhanced contact area, low resistance, and a safe, sealed terminal connection for critical electrical circuits, especially with larger and high-capacity conductors.Q: What are the main benefits of tin plating on these lugs?

A: Tin plating provides excellent resistance to corrosion and oxidation, extending the life of the cable lug and maintaining high conductivity even in harsh conditions. This reduces maintenance frequency and ensures long-term reliability.Q: Where can I source these cable lugs in India?

A: You can acquire these tubular compression cable lugs directly from specialized manufacturers or suppliers in India who cater to the electrical and power distribution market. Many suppliers offer varying sizes and configurations based on your project requirement.Q: What specifications should be checked before choosing the right lug?

A: Ensure compatibility by matching the cable diameter (1.5 mm630 mm), stud hole size, lug thickness (0.82.5 mm), and required rated voltage (up to 1100 V) with your installation needs. Also, verify if the insulation and contact resistance ratings align with safety standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cable Lugs Category

Soldering Copper Cable Lugs

Minimum Order Quantity : as per requirement Piece

Weight : 45 grams (varies with size)

Insulation Resistance : >=1000 M

Sealed : Other, Unsealed

Rated Voltage : Up to 1100V

Style : Tubular Lug

Send Inquiry

Send Inquiry