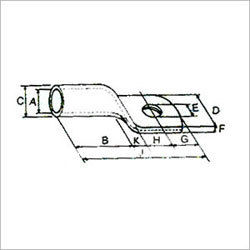

Soldering Copper Cable Lugs

Soldering Copper Cable Lugs Specification

- Sealed

- Unsealed

- Product Type

- Soldering Copper Cable Lug

- Material

- High conductivity ETP copper

- Contact Resistance

- <0.2 m

- Insulation Resistance

- >=1000 M

- Terminal Socket

- Copper Barrel

- Style

- Tubular Lug

- Fittings

- Crimp or solder connection

- Rated Voltage

- Up to 1100V

- Weight

- 45 grams (varies with size)

Soldering Copper Cable Lugs Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Delivery Time

- depends on quantity Week

- Sample Available

- Yes

- Packaging Details

- carton packing

- Main Domestic Market

- All India

About Soldering Copper Cable Lugs

Soldering Copper Cable Lugs

We are able to carve a niche for ourselves in this domain by manufacturing and supplying an impeccable range of Soldering Copper Cable Lugs. Manufactured using finest grade copper obtained from the reliable vendors of the market, the cable lugs are extensively demanded in various industrial as well as in electrical sectors. Before final delivery, these lugs are stringently checked on various quality parameters. Our customers can avail these Soldering Copper Cable Lugs in various sizes ranging from 6mm2 to 625mm2 to suit their needs.

Features

- Rust resistance

- Longer working life

- Precise design

Versatile Solder and Crimp Connections

These copper cable lugs are engineered for both soldered and crimped installations, providing flexibility based on your specific electrical setup. Whether you prefer the security of soldering or the convenience of crimping, these lugs accommodate a variety of connection preferences while maintaining low contact resistance for enhanced power flow.

High Conductivity and Insulation Performance

Constructed from ETP copper, our lugs ensure optimal electrical conductivity. With insulation resistance of at least 1000 M and a contact resistance below 0.2 m, these lugs minimize energy loss and support safe, reliable operation in high-voltage environments up to 1100V.

FAQs of Soldering Copper Cable Lugs:

Q: How do I solder these copper cable lugs for optimal connection?

A: To solder these lugs, strip the cable insulation, insert the conductor into the lugs copper barrel, and apply heat with a suitable soldering iron. Feed solder into the joint until it flows evenly, ensuring strong mechanical and electrical contact. Allow the connection to cool naturally before use.Q: What are the benefits of using ETP copper in these cable lugs?

A: ETP (Electrolytic Tough Pitch) copper offers superior electrical conductivity, which enhances energy efficiency and reduces heat build-up. Its high purity and excellent mechanical strength ensure reliable and long-lasting performance for demanding electrical installations.Q: When should I choose a solder connection over a crimp connection with these lugs?

A: Solder connections are ideal when you require a permanent, vibration-resistant bond, particularly in environments where maximum electrical continuity is critical. Crimp connections, however, are faster and more convenient for applications needing frequent disassembly or field work.Q: Where can these copper cable lugs be used?

A: These tubular lugs are suitable for industrial, commercial, and certain residential electrical projects. Applications include connecting power cables in switchboards, control panels, distribution boxes, and automotive wiring where high conductivity and durability are important.Q: What is the process for fitting these lugs onto copper conductors?

A: Begin by appropriately stripping the insulation from the copper conductor. Insert the stripped end into the lugs copper barrel and secure it using either a soldering iron for soldered connections or a crimping tool for crimped connections. Ensure the joint is tight and free from movement to maintain optimal electrical contact.Q: How does the insulation resistance of these lugs benefit users?

A: With an insulation resistance equal to or exceeding 1000 M, these lugs help prevent leakage currents, reduce the risk of short circuits, and enhance overall electrical safety. This makes them well-suited to high-voltage and sensitive applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cable Lugs Category

Tubular Compression Cable Lugs

Minimum Order Quantity : as per requirement Piece

Weight : Varies as per size (approx. 5g 250g)

Thickness : 0.8 2.5 mm depending on lug size

Sealed : Other, Unsealed

Insulation Resistance : 1000 M

Material : Other, Electrolytic copper

Send Inquiry

Send Inquiry