Crimping Ferrules

Crimping Ferrules Specification

- Surface Treatment

- Tin Plated, Corrosion Resistant

- Cable Diameter

- Varies as per size (0.5 mm to 25 mm as standard)

- Product Type

- Crimping Ferrules

- Material

- Copper with tin plating / Aluminum

- Contact Resistance

- Low

- Diameter

- Varies by model (e.g. 1.1mm, 2.5mm, etc.)

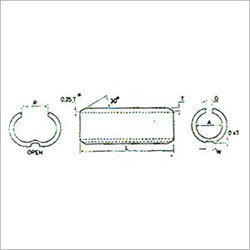

- Style

- Tube type

- Color

Crimping Ferrules Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Delivery Time

- depends on quantity Week

- Sample Available

- Yes

- Packaging Details

- carton packing

- Main Domestic Market

- All India

About Crimping Ferrules

Copper Ferrules

We manufacture a wide range of Copper Ferrules as per established quality standards. These are manufactured from electrolytic copper and are used to join low voltage conductors. Connectors are provided with a dimple (if required) which acts as a conductor stop and ensures correct positioning. Our range is tin plated to prevent corrosion.

Versatile Range for Multiple Applications

Crimping ferrules come in various colors and diameters, catering to a wide spectrum of cable sizes and coding needs. Their robust construction, utilizing copper with tin-plating or aluminum, ensures suitability for everything from control panels to heavy-duty industrial equipment. The corrosion-resistant properties further augment their reliability and longevity in diverse environmental conditions.

Reliable and Easy Installation Process

Designed with standardized dimensions and quality surface treatment, these ferrules guarantee quick and efficient installation. By crimping the ferrule onto stripped wire ends, users achieve a secure, vibration-resistant cable termination that minimizes contact resistance and enhances safety. This process is straightforward and can be accomplished with common crimping tools.

FAQs of Crimping Ferrules:

Q: How are crimping ferrules used in electrical wiring?

A: Crimping ferrules are used to terminate stranded wires, providing a secure end connection. After stripping the wire, the ferrule is slipped over the conductor and compressed with a suitable crimping tool, ensuring solid electrical contact and preventing strand fraying.Q: What types of crimping ferrules are available regarding color and material?

A: These ferrules are available in multiple colorsincluding red, blue, yellow, black, green, grey, white, and brownfor easy identification. They are made from copper with tin plating or aluminum to suit diverse electrical and environmental requirements.Q: When should I use crimping ferrules in my wiring projects?

A: Crimping ferrules are recommended whenever you need a durable and low-resistance cable termination, particularly in control panels, distribution boards, or anywhere secure, corrosion-resistant connections are crucial.Q: Where are crimping ferrules commonly installed?

A: Crimping ferrules are widely used in industrial automation, power distribution, commercial and residential wiring systems across India, and wherever consistent electrical connections are necessary.Q: What is the process for installing a tube-type crimping ferrule?

A: First, strip the insulation off the wire end, then slide the appropriate size ferrule onto the wires. Using a compatible crimping tool, compress the ferrule until it securely encloses the strands, resulting in a reliable, corrosion-resistant termination.Q: What are the benefits of using tin-plated, corrosion-resistant ferrules?

A: Tin-plated ferrules offer enhanced protection against oxidation and moisture, ensuring long service life. Their corrosion resistance and low contact resistance improve both safety and performance of electrical installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electronic Products Category

Aluminium Tubular Terminal Ends

Minimum Order Quantity : 200 Pieces

Sealed : Other, Nonsealed

Application : Electrical cable termination and power distribution

Terminal Socket : Tubular

Material : Brass, Copper, Aluminum

Contact Resistance : < 0.002

Aluminium Ferrules

Minimum Order Quantity : 500 Pieces

Sealed : NO

Application : Cable jointing, mechanical fastening

Terminal Socket : Not included

Material : Other, Aluminium

Contact Resistance : Low

Copper End Sealing Ferrules

Minimum Order Quantity : as per requirement Piece

Sealed : NO

Application : Wire Harnessing and Cable Ends

Terminal Socket : Single Hole

Material : Other, Copper (Tin Plated)

Contact Resistance : < 2 m

Copper Crimping End Sealing Ferrules

Minimum Order Quantity : as per requirement Piece

Sealed : Yes

Application : Panel Wiring, Electrical Installations

Terminal Socket : Closed End

Material : Other, High Conductivity Copper

Contact Resistance : 0.01 m

Send Inquiry

Send Inquiry