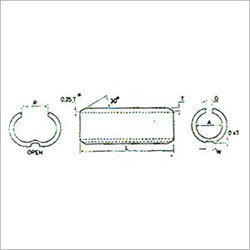

Copper Crimping End Sealing Ferrules

Copper Crimping End Sealing Ferrules Specification

- Sealed

- Yes

- Product Type

- End Sealing Ferrule

- Material

- High Conductivity Copper

- Application

- Panel Wiring, Electrical Installations

- Contact Resistance

- 0.01 m

- Insulation Resistance

- 1000 M

- Terminal Socket

- Closed End

- Style

- Tube Type

- Fittings

- Crimp Connection

- Rated Voltage

- 600 V

Copper Crimping End Sealing Ferrules Trade Information

- Payment Terms

- Cheque, Cash Advance (CA)

- Delivery Time

- depends on quantity Week

- Sample Available

- Yes

- Packaging Details

- carton packing

- Main Domestic Market

- All India

About Copper Crimping End Sealing Ferrules

We are pleased to introduce ourselves as one of the eminent manufacturers and suppliers of Copper Crimping End Sealing Ferrules. Precisely manufactured using high grade copper and latest technology, these products are quality tested on various characteristics to make sure that only defect-free products are delivered at customers premises. Widely used for reducing the risk of cable breakage, these Copper Crimping End Sealing Ferrules are also used when a perfect connection is needed at the end of a cable.

Features

- High tensile strength

- Trouble free operation

- User friendly

Enhanced Electrical Safety and Performance

The closed-end, sealed construction of these tube-style copper crimping ferrules guarantees secure electrical connections, reducing the risk of shorts or corrosion. With high insulation resistance and low contact resistance, they deliver consistent current flow and dependable operation, making them vital for robust panel wiring.

Premium Materials and Reliable Design

Engineered from high conductivity copper, these ferrules offer superior electrical efficiency and durability. The crimp connection method provides a mechanical and electrical bond, preventing loose terminals and supporting long-term stability in demanding electrical installations.

FAQs of Copper Crimping End Sealing Ferrules:

Q: How are copper crimping end sealing ferrules used in electrical installations?

A: Copper crimping end sealing ferrules are inserted over the stripped end of a wire, then compressed with a crimping tool to create a secure, closed connection. This process prevents wire strands from fraying and ensures a reliable link within terminal blocks or connector sockets.Q: What benefits do these sealed copper ferrules provide for panel wiring?

A: Sealed copper ferrules provide enhanced electrical safety by fully enclosing the wire end, preventing accidental shorts and corrosion. Their high conductivity and low contact resistance ensure efficient power transmission in panel wiring applications.Q: Where are these tube-type copper ferrules commonly applied?

A: These ferrules are widely used in panel wiring, control cabinets, and various electrical installations where dependable, sealed wire terminations are necessary. Their application is common in industrial, residential, and commercial settings across India.Q: What is the recommended process for installing these ferrules?

A: To install, strip the wire end, slide the ferrule over the exposed conductor, and use a suitable crimping tool to compress the ferrule. This step creates a robust electrical and mechanical connection, ready for insertion into terminal sockets.Q: When is it advisable to use closed-end crimping ferrules in a project?

A: Closed-end crimping ferrules are recommended whenever secure, sealed wire terminations are necessary, particularly in high-density panels or environments where stray strands or moisture could pose a risk.Q: How does the material composition enhance the performance of these ferrules?

A: Constructed from high conductivity copper, these ferrules minimize power loss and support efficient current flow, while their robust sealed design ensures long-term durability even in demanding installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electronic Products Category

Aluminium Tubular Terminal Ends

Price Range 10.00 - 60.00 INR / Piece

Minimum Order Quantity : 200 Pieces

Contact Resistance : < 0.002

Surface Treatment : Other, Tin plated for corrosion protection

Style : Straight barrel

Cable Diameter : 1.5 mm to 1000 mm

Aluminium Ferrules

Price Range 100.00 - 1000.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Contact Resistance : Low

Surface Treatment : Other, Polished/Plain

Style : Round Sleeve

Cable Diameter : Available for 1 mm to 10 mm cable sizes

Copper End Sealing Ferrules

Minimum Order Quantity : as per requirement Piece

Contact Resistance : < 2 m

Surface Treatment : Other, Tin Plated

Style : End Sealing Ferrule

Cable Diameter : 0.25 mm to 16 mm

Crimping Ferrules

Minimum Order Quantity : as per requirement Piece

Contact Resistance : Low

Surface Treatment : Other, Tin Plated, Corrosion Resistant

Style : Tube type

Cable Diameter : Varies as per size (0.5 mm to 25 mm as standard)

Send Inquiry

Send Inquiry