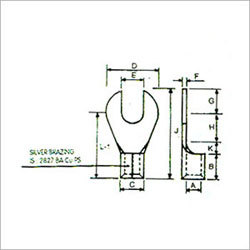

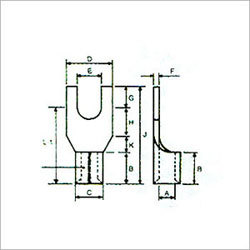

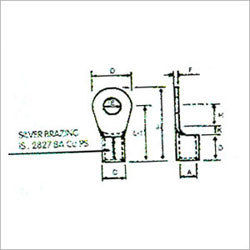

Copper Tubular Cable Terminal Ends

Copper Tubular Cable Terminal Ends Specification

- Sealed

- Non-sealed

- Surface Treatment

- Electro Tin Plated

- Thickness

- 0.8mm - 2.5mm

- Cable Diameter

- 1.5mm to 500mm

- Product Type

- Tubular Cable Terminal Ends

- Material

- Copper, Aluminum

- Application

- Power Distribution, Panel Wiring

- Contact Resistance

- Less than 0.2 m

- Insulation Resistance

- Greater than 1000 M

- Diameter

- Varies according to cable size

- Terminal Socket

- Tubular Type

- Style

- Tubular

- Fittings

- Suitable for Crimping Applications

- Rated Voltage

- Up to 1000V

- Weight

- Varies as per size (typically 5g to 50g per terminal)

- Color

- Natural Copper

Copper Tubular Cable Terminal Ends Trade Information

- Minimum Order Quantity

- 200 Pieces

- FOB Port

- Mumbai

- Main Domestic Market

- All India

About Copper Tubular Cable Terminal Ends

We have emerged as a pioneer in manufacturing and supplying a wide range of Copper Tubular Cable Terminal Ends to our esteemed patrons. These terminals are designed using superb quality copper that is obtained from the most trustworthy vendors of the market. Further, our quality controllers strictly check each product on various parameters before dispatching to our customers end. Find its extensive usage in different sectors, the offered Copper Tubular Cable Terminal Endsl is provided to the customers at feasible price.

Features

- High tensile strength

- Low maintenance

- Long working life

Reliable Performance in Demanding Environments

Engineered to withstand operating temperatures from -55C to +105C, these terminal ends ensure lasting performance even in harsh conditions. Their non-flammable nature, robust tensile strength, and Electro Tin Plating deliver exceptional safety and longevity. This makes them a dependable choice for critical power distribution and industrial panel wiring tasks.

Optimized for Versatility and Installation Ease

Available in a wide range of sizes, these lugs are compatible with cables from 1.5mm to 500mm and fit bolt sizes from M4 up to M16. The smooth and bright finish allows for easy handling and installation, while the crimping tool requirement ensures a secure, long-lasting connection. Packaged according to various needs, they integrate seamlessly into modern electrical projects.

FAQs of Copper Tubular Cable Terminal Ends:

Q: How do I install Copper Tubular Cable Terminal Ends?

A: These terminal ends are installed using a suitable crimping tool. After stripping the cable to the required length, insert the cable into the terminal, and crimp firmly to ensure a secure and conductive connection according to recommended standards.Q: What applications are suitable for these terminal ends?

A: They are ideal for power distribution, panel wiring, and a variety of industrial and electrical connections where reliable conductivity and high corrosion resistance are required, especially in equipment rated up to 1000V.Q: When should I choose a specific terminal size or hole diameter?

A: Select terminal ends based on the cross-sectional area of your cable (from 1.5mm to 500mm) and the appropriate bolt diameter (M4 to M16) for your installation. Choosing the correct size ensures a secure electrical and mechanical fit.Q: What is the primary benefit of the electro tin-plated surface treatment?

A: Electro tin plating offers enhanced corrosion resistance, lower contact resistance (less than 0.2 m), and maintains excellent conductivity, making the terminals appropriate for long-term, demanding applications.Q: Are these terminals compliant with global safety standards?

A: Yes, these Copper Tubular Cable Terminal Ends are manufactured according to IEC standards for tensile and insulation resistance, are RoHS compliant, and clearly marked with size and brand for traceability.Q: What is the process for selecting the correct terminal for my project?

A: Identify the cable size and type, confirm the operational voltage (up to 1000V), and ensure compatibility with your chosen bolt size. Select the terminal lug with matching specifications, and use a certified crimping tool for installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Terminals Category

Copper Ring Tongue Fork Terminal

Minimum Order Quantity : as per requirement Piece

Application : Electrical connections, Panel Wiring, Switchgear

Surface Treatment : Other, Tin Plated

Material : Other, Pure Copper

Contact Resistance : 0.01

Rated Voltage : 600 Volts

Copper Rectangular Tongue Fork Terminals

Minimum Order Quantity : as per requirement Piece

Application : Used in switchboards, power distribution, automotive

Material : Other, High conductivity copper

Contact Resistance : 1 m

Rated Voltage : Up to 600V

Copper Ring Tongue Terminal Ends

Minimum Order Quantity : 10 Pieces

Application : Battery, Electronic Products, Electric Appliances, Wire Connection, Power switches, Miniature switches, Home Appliances, Automotive, Machinery

Surface Treatment : Silver Plated

Tubular Terminals

Minimum Order Quantity : 200 Pieces

Application : Battery, Electronic Products, Electric Appliances, Wire Connection, Power switches, Miniature switches, Consumer Electronics, Home Appliances, Automotive, Stationery, Machinery

Surface Treatment : Silver Plated

Send Inquiry

Send Inquiry