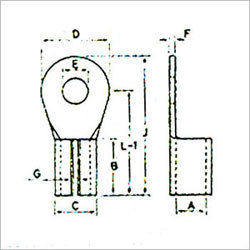

Copper Ring Tongue Terminal Ends

Copper Ring Tongue Terminal Ends Specification

- Surface Treatment

- Silver Plated

- Application

- Battery, Electronic Products, Electric Appliances, Wire Connection, Power switches, Miniature switches, Home Appliances, Automotive, Machinery

Copper Ring Tongue Terminal Ends Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Mumbai

- Delivery Time

- Week

- Sample Available

- Yes

- Packaging Details

- carton packing

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Copper Ring Tongue Terminal Ends

Copper Ring Tongue Terminal Ends

We have a flair for manufacturing customized products as per the specific requirements of our clients. Our range of terminal ends includes copper terminal ends, aluminum terminal ends, copper ring tongue fork terminal ends that are electro tinned to provide protection from corrosion and oxidation.

Versatile Applications

Copper Ring Tongue Terminal Ends are highly adaptable and used across numerous sectors, from automotive wiring and industrial machinery to home and electronic appliances. Their compatibility with different devices makes them a reliable option for creating stable electrical connections.

Exceptional Conductivity & Durability

With a silver-plated surface treatment, these terminals enhance electrical conductivity and resist corrosion, ensuring a long-lasting, stable connection. The copper base material provides strength and durability, suitable for both high and low-current applications.

Easy Installation Process

The ring tongue shape allows for straightforward installation by crimping or soldering onto the wires, as well as secure attachment to studs or terminal blocks. This design ensures a strong, vibration-resistant connection routinely required in automotive and machinery settings.

FAQs of Copper Ring Tongue Terminal Ends:

Q: How are Copper Ring Tongue Terminal Ends installed?

A: Copper Ring Tongue Terminal Ends can be installed using a crimping tool to secure the terminal onto a stripped wire, or by soldering for an enhanced bond. The ring tongue then fits onto a stud or terminal post, ensuring a tight and stable connection.Q: What are the main benefits of using these terminal ends?

A: The primary benefits include excellent electrical conductivity, enhanced by the silver-plated surface, strong corrosion resistance, straightforward installation, and reliable performance even in environments subject to vibration or thermal fluctuations.Q: When should Copper Ring Tongue Terminal Ends be used?

A: These terminals are ideal for use when a secure, low-resistance electrical connection is required, such as in battery connections, home appliances, automotive wiring, and machinery. They are particularly valuable where reliability and durability are crucial.Q: Where are these terminal ends typically used?

A: They are commonly found in battery terminals, electronic devices, power and miniature switches, home and electric appliances, as well as in automotive and industrial machinery wiring.Q: What is the manufacturing process for these terminal ends?

A: The process involves precision forming of copper, followed by silver plating for enhanced conductivity and protection against corrosion. The terminals are then shaped and finished to ensure a reliable fit and secure connection during installation.Q: How does the silver plating improve their performance?

A: Silver plating provides a layer that not only increases electrical conductivity but also offers protection against oxidation and corrosion, making the terminal ends more suitable for demanding and long-term applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Terminals Category

Copper Tubular Cable Terminal Ends

Minimum Order Quantity : 200 Pieces

Application : Power Distribution, Panel Wiring

Material : Copper, Aluminum

Surface Treatment : Other, Electro Tin Plated

Style : Tubular

Insulation Resistance : Greater than 1000 M

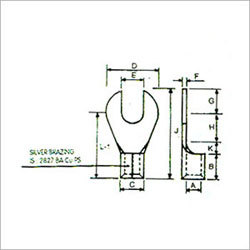

Copper Ring Tongue Fork Terminal

Minimum Order Quantity : as per requirement Piece

Application : Electrical connections, Panel Wiring, Switchgear

Material : Other, Pure Copper

Surface Treatment : Other, Tin Plated

Style : Ring Tongue Fork

Insulation Resistance : 1000 M

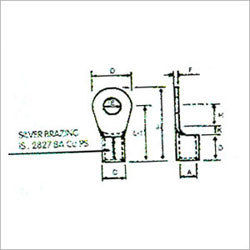

Open Close Type Soldering Cable Terminal End

Minimum Order Quantity : as per requirement Piece

Application : Suitable for electrical wiring in automotive, machinery, and panel construction

Material : Other, Copper with tin plating

Surface Treatment : Other, Tin Plated

Style : Open Close Type

Insulation Resistance : 1000 M at 500V DC

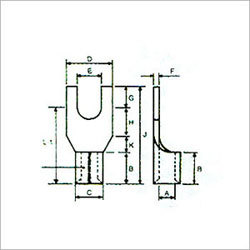

Copper Rectangular Tongue Fork Terminals

Minimum Order Quantity : as per requirement Piece

Application : Used in switchboards, power distribution, automotive

Material : Other, High conductivity copper

Style : Rectangular tongue fork

Insulation Resistance : Greater than 1000 M

Send Inquiry

Send Inquiry