Copper Crimping Reducer Terminals

Price 10 INR/ Piece

Copper Crimping Reducer Terminals Specification

- Application

- Battery, Electronic Products, Electric Appliances, Wire Connection, Power switches

- Surface Treatment

- Silver Plated

Copper Crimping Reducer Terminals Trade Information

- Minimum Order Quantity

- 200 Pieces

- FOB Port

- Mumbai

- Delivery Time

- Week

- Sample Available

- Yes

- Packaging Details

- carton packing

- Main Domestic Market

- All India

About Copper Crimping Reducer Terminals

We have achieved an enviable position for manufacturing and supplying an expansive range of Copper Crimping Reducer Terminals that are widely used for terminating one or more aluminium conductors to a smaller termination area. The offered terminals are manufactured using high grade copper and latest technology in compliance with set industry standards. Our Copper Crimping Reducer Terminals are available in different grades and dimensions as per the customers requirement.

Features

- Non corrosive in nature

- Dimensionally accurate

- Easy maintenance

Further Details

Copper Crimping Reducer Terminals are used to terminate one or more aluminium conductors to a smaller termination area. These type of terminals are applicable in tunnel type terminal blocks viz. fuse gears, cut-outs, meters etc. Braco is able to produce any copper reducing link that you may require.

Superior Conductivity and Corrosion Resistance

The silver-plated finish on these copper crimping reducer terminals not only boosts electrical conductivity but also shields against corrosion. This makes them ideal for applications requiring consistent performance and longevity, particularly in environments exposed to moisture or variable temperatures.

Versatile Applications Across Industries

Engineered for compatibility with various electronic products, battery connections, electric appliances, wire assemblies, and power switches, these terminals serve as a vital component in both consumer and industrial settings. Their adaptability ensures secure, low-resistance connections in diverse use cases.

FAQs of Copper Crimping Reducer Terminals:

Q: How are Copper Crimping Reducer Terminals with silver plating used in electronic products and batteries?

A: These terminals are crimped onto wires to establish secure, low-resistance connections in electronic devices, batteries, and electric appliances. Their silver surface ensures optimal conductivity, making them suitable for critical applications such as battery systems and power switches.Q: What process is involved in the silver plating of these copper terminals?

A: The silver plating process involves electrochemically bonding a thin layer of silver onto the copper terminals surface. This enhances conductivity and guards against oxidation, resulting in a terminal that offers superior electrical performance and durability.Q: When should one select a silver-plated copper crimping terminal over a standard version?

A: Silver-plated copper crimping terminals are ideal when consistent conductivity and resistance to corrosion are crucial. They are preferred in applications that experience frequent current loads, moisture, or require reliable long-term connections, such as electric appliances and power systems.Q: Where are these Copper Crimping Reducer Terminals typically manufactured and supplied from?

A: These terminals are produced by manufacturers and suppliers in India, catering to both domestic and international markets. Indian manufacturers ensure quality standards while offering cost-effective solutions for diverse industrial needs.Q: What are the advantages of using silver-plated copper terminals for wire connection?

A: The main benefits include excellent conductivity, improved corrosion resistance, and reliable mechanical strength. This combination guarantees minimal power loss and long-lasting electrical connections in a variety of settings, from home electronics to industrial equipment.Q: How does the installation process for these terminals ensure a secure wire connection?

A: The installation involves inserting the stripped wire into the terminal and applying a crimping tool. This action deforms the metal, creating a tight mechanical and electrical bond that remains secure even under stress, vibration, or temperature changes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Terminals Category

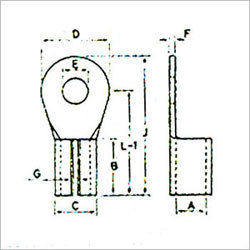

Copper Tubular Cable Terminal Ends

Minimum Order Quantity : 200 Pieces

Application : Power Distribution, Panel Wiring

Surface Treatment : Other, Electro Tin Plated

Material : Copper, Aluminum

Contact Resistance : Less than 0.2 m

Rated Voltage : Up to 1000V

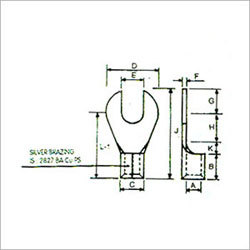

Copper Ring Tongue Fork Terminal

Minimum Order Quantity : as per requirement Piece

Application : Electrical connections, Panel Wiring, Switchgear

Surface Treatment : Other, Tin Plated

Material : Other, Pure Copper

Contact Resistance : 0.01

Rated Voltage : 600 Volts

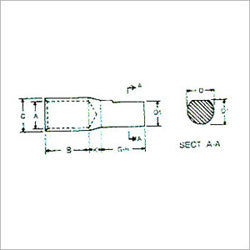

Open Close Type Soldering Cable Terminal End

Minimum Order Quantity : as per requirement Piece

Application : Suitable for electrical wiring in automotive, machinery, and panel construction

Surface Treatment : Other, Tin Plated

Material : Other, Copper with tin plating

Contact Resistance : 0.5 m

Rated Voltage : 600V

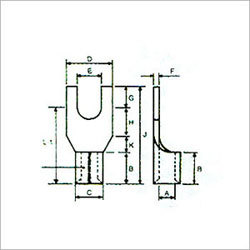

Copper Rectangular Tongue Fork Terminals

Minimum Order Quantity : as per requirement Piece

Application : Used in switchboards, power distribution, automotive

Material : Other, High conductivity copper

Contact Resistance : 1 m

Rated Voltage : Up to 600V

Send Inquiry

Send Inquiry